Executive Summary

The Asia-Pacific Torque Vectoring Market is undergoing rapid expansion, primarily driven by the region's status as a global hub for electric vehicle (EV) manufacturing and the increasing consumer preference for high-performance passenger cars. As of 2026, the market is characterized by significant technological shifts from traditional mechanical differentials to advanced electronic torque vectoring systems. China, Japan, and India are the pivotal markets, benefiting from a robust automotive supply chain and favorable government incentives for vehicle electrification.

https://www.databridgemarketresearch.com/reports/asia-pacific-torque-vectoring-market

Market Overview

Torque vectoring is an advanced technology that provides the ability to vary the torque to each wheel independently, significantly improving vehicle handling, traction, and safety. In the Asia-Pacific region, the demand is heavily influenced by the proliferation of luxury SUVs and the rise of Software-Defined Vehicles (SDV). The integration of torque vectoring with Advanced Driver Assistance Systems (ADAS) is a major focus for regional OEMs as they seek to meet rigorous safety standards and enhance the driving experience in increasingly congested urban environments.

Market Size & Forecast

The Asia-Pacific region holds the largest market share globally for torque vectoring systems. The market was valued at approximately USD 4.85 Billion in 2025 and is projected to reach USD 11.24 Billion by 2033.

- Base Year: 2025

- Estimated Market Value (2026): USD 5.46 Billion

- Projected Market Value (2033): USD 11.24 Billion

- CAGR: 11.4% (2025–2033)

Market Segmentation

The Asia-Pacific market is segmented based on technology, propulsion, vehicle type, and clutch actuation:

- By Technology:

- Active Torque Vectoring Systems (ATVS): The fastest-growing segment, favored in EVs for its millisecond-response precision.

- Passive Torque Vectoring Systems (PTVS): Commonly used in budget-friendly passenger vehicles and light trucks.

- By Propulsion:

- Electric Vehicles (BEV/PHEV): Dominant growth driver in China and South Korea.

- Internal Combustion Engine (ICE): Still prevalent in Southeast Asian markets and India.

- By Driving Wheel Type:

- All-Wheel Drive (AWD)/Four-Wheel Drive (4WD): Largest segment due to the rising popularity of SUVs.

- Front-Wheel Drive (FWD) and Rear-Wheel Drive (RWD).

- By Vehicle Type:

- Passenger Cars: Includes luxury sedans and the high-growth crossover/SUV segment.

- Commercial Vehicles: Increasing adoption in electric delivery vans and light trucks.

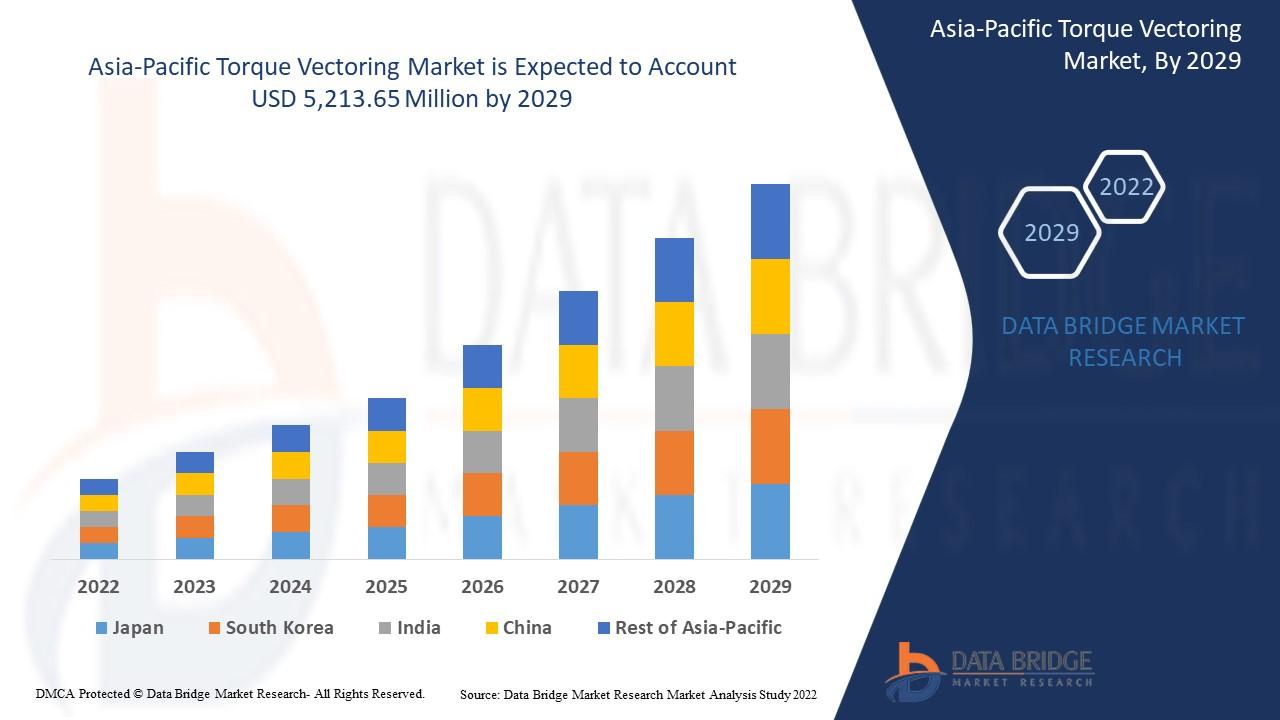

Regional Insights

China stands as the largest contributor to the Asia-Pacific market, driven by its massive EV production capacity and the rapid adoption of dual-motor and quad-motor configurations. Japan remains a technological leader, with companies like Toyota and Nissan pioneering hybrid torque management. India is emerging as a high-potential market, with a projected CAGR of over 15%, fueled by increasing localized production of premium SUVs and the gradual shift toward green mobility.

Competitive Landscape

The regional competitive landscape features a mix of global Tier-1 suppliers and aggressive domestic players focusing on cost-effective electronic control modules.

Top Market Players:

- JTEKT Corporation (Japan)

- Robert Bosch GmbH (Germany/APAC Operations)

- GKN Automotive Limited (UK/China Joint Ventures)

- BorgWarner Inc. (US/India Operations)

- Hyundai Mobis (South Korea)

- Aisin Seiki Co., Ltd. (Japan)

- Continental AG (Germany/APAC Operations)

- ZF Friedrichshafen AG (Germany/APAC Operations)

https://www.databridgemarketresearch.com/reports/asia-pacific-torque-vectoring-market/companies

Trends & Opportunities

- In-Wheel Motor Technology: Research into in-wheel motor architectures in Japan and China is opening new frontiers for absolute wheel-specific torque control.

- AI-Driven Algorithms: Use of artificial intelligence for predictive torque distribution based on real-time road condition sensing.

- Electrification of LCVs: Growing opportunities in the logistics sector for electric delivery vehicles requiring high stability during heavy-load cornering.

Challenges & Barriers

- High System Integration Costs: In price-sensitive markets like India and Southeast Asia, the high cost of active torque vectoring components remains a barrier for mass-market vehicles.

- Semiconductor Shortages: Continued volatility in the supply of high-end automotive chips can disrupt the production of electronic torque control units.

- Technical Complexity: The need for extensive R&D to synchronize torque vectoring with regenerative braking in electric powertrains.

Conclusion

The Asia-Pacific Torque Vectoring Market is set to lead global growth as the region accelerates its transition to electric mobility. While infrastructure and cost challenges persist, the relentless drive toward vehicle safety and high-performance standards ensures a robust future for torque distribution technologies across the continent.

https://www.databridgemarketresearch.com/reports/asia-pacific-torque-vectoring-market

Browse Trending Report: Asia-Pacific Torque Vectoring Market

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email: corporatesales@databridgemarketresearch.com