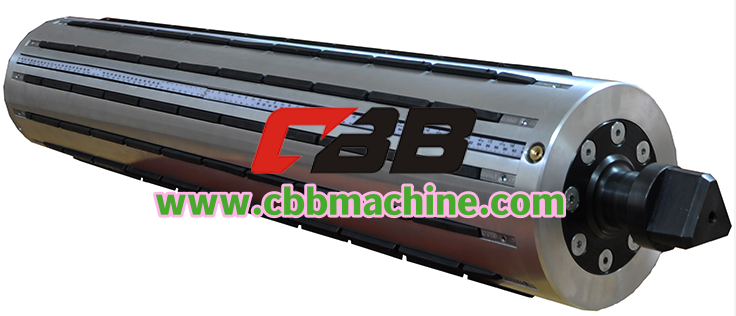

In converting and slitting operations where consistent roll tension is critical, the Differential Air Shaft from Cbbmachine provides an intelligent solution that enhances both accuracy and productivity. Designed for multiple web widths and diverse substrates, this shaft ensures even tension distribution across each roll core—reducing defects and improving roll quality from the inside out.

The key to its performance lies in its ability to automatically adjust torque through pneumatic force. As the web rewinds, the shaft compensates for variations in roll diameter, material thickness, or friction by distributing air pressure evenly among internal friction elements. This mechanism allows each roll to rotate independently while maintaining synchronized tension, ensuring smooth and uniform winding across all cores.

The structure is robust, lightweight, and precisely engineered to minimize runout and vibration. It can be seamlessly integrated into existing or new machinery, supporting high-speed lines without sacrificing control. Operators benefit from tool-free core loading, fast inflation and deflation cycles, and reliable locking that holds even under demanding workloads.

For industries handling plastic film, paper, foil, and flexible laminates, this technology provides a competitive edge. It helps eliminate issues like telescoping, wrinkling, or uneven edges, reducing material waste and machine downtime. Whether used in label converting, flexible packaging, or laminating lines, the differential air shaft adds measurable value by enhancing output quality.

Beyond its core functionality, it also offers customization options to match varying core sizes, machine specifications, and production needs. The long operational life and minimal maintenance requirements translate into lower ownership costs over time, while still delivering high-end performance round after round.

The evolution of tension control starts with smarter mechanical design. This shaft doesn't just hold rolls in place—it actively contributes to the quality and efficiency of every finished product.

Looking to add intelligence to your winding operations? Visit https://www.cbbmachine.com/product/ today and discover how the right shaft can help your machines think ahead—automating precision with every turn.