Safety is the foundation of every maintenance operation, and docking systems are at the heart of that mission. The US Aircraft Docking Systems Market has evolved to prioritize worker safety, ergonomic design, and operational reliability.

Industry Growth and Safety Regulations

With increased maintenance requirements, safety standards have become more rigorous. Recent industry growth patterns show maintenance centers adopting advanced docking systems that comply with both domestic and international aviation safety norms.

These systems provide stable platforms, protective railings, and anti-slip surfaces that prevent workplace accidents. They also enhance the precision of inspections and repairs by offering stable access points to complex aircraft components.

Ergonomic Design for Technicians

Modern docking platforms are ergonomically designed to minimize technician fatigue. Adjustable heights, integrated lighting, and easy mobility contribute to a safer and more comfortable working environment. This not only improves safety but also boosts overall productivity in maintenance operations.

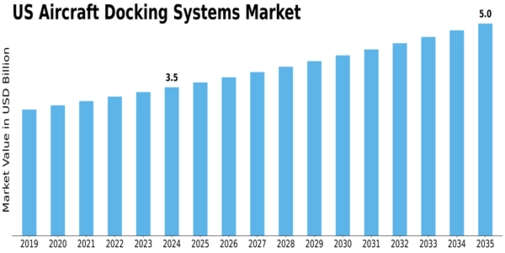

Market Forecast

The market forecast highlights further advancements in safety-focused systems, including smart warning indicators, load sensors, and automated balancing technologies. The ongoing shift toward intelligent docking solutions aligns with global aviation safety objectives.

FAQs

1. What safety features are common in modern docking systems?

They include guardrails, anti-slip flooring, integrated lighting, and adjustable height functions for ergonomic access.

2. How do docking systems contribute to aviation safety?

By providing stable, reliable, and secure maintenance platforms that reduce the risk of accidents and enhance precision work.