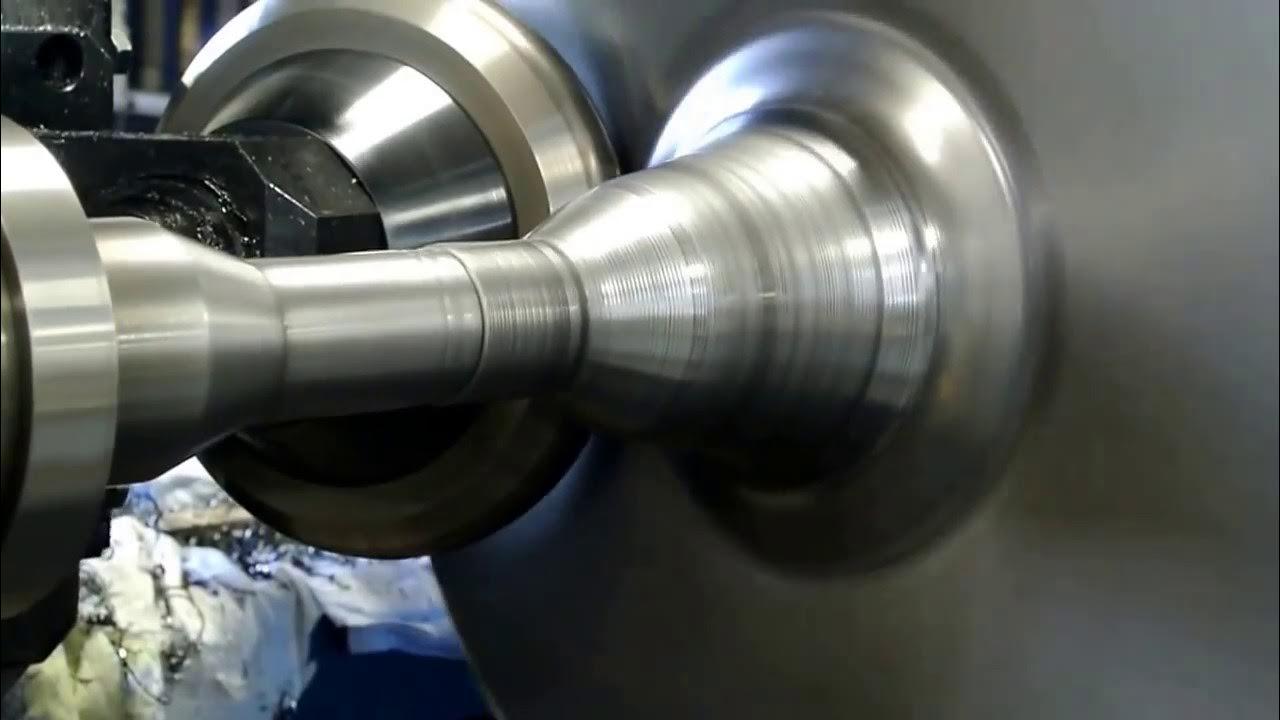

The global metal spinning products market has gained significant momentum in recent years due to its ability to deliver precision engineered, lightweight, and cost effective metal components across a wide range of industrial applications. Metal spinning is a manufacturing process used to form cylindrical or symmetrical metal parts by rotating a metal disc or tube at high speed and shaping it over a mandrel. This process offers excellent material utilization, enhanced structural strength, and superior surface finish compared to conventional metal forming methods. As industries increasingly seek efficiency, durability, and design flexibility, metal spinning products are becoming a preferred choice for manufacturers worldwide.

The market is particularly influenced by growth in automotive, aerospace, construction, electronics, and industrial machinery sectors. These industries require high performance components that can withstand mechanical stress while maintaining dimensional accuracy. Metal spinning fulfills these requirements while also supporting sustainability goals through reduced material waste and energy efficiency. As a result, the metal spinning products market continues to expand steadily across both developed and emerging economies.

Market Overview and Industry Significance

According to persistence market research The global metal spinning products market size is likely to be valued at US$ 3.0 billion in 2026 and is estimated to reach US$ 4.0 billion by 2033, growing at a CAGR of 4.2% during the forecast period 2026−2033. The market’s expansion is driven by increased adoption of precision engineered metal components across the automotive, aerospace, and construction industries. Rising demand for lightweight and durable materials, especially aluminum and stainless steel, further supports market growth. Technological advancements in computer numerical control CNC metal spinning and rising investments in industrial manufacturing capabilities strengthen long term market prospects.

This growth trajectory highlights the rising importance of metal spinning as a core manufacturing technology. Its ability to produce complex shapes with consistent quality positions it as a strategic process for industries focused on innovation and performance optimization.

Key Characteristics of Metal Spinning Products

Metal spinning products are widely valued for their mechanical properties and design versatility. Some of the most important characteristics contributing to market growth include high strength to weight ratio which makes components suitable for demanding applications improved material efficiency resulting in reduced scrap and lower production costs excellent surface finish and uniform wall thickness compatibility with a wide range of metals such as aluminum stainless steel copper brass and steel flexibility in producing both small batch and large volume components

These characteristics enable manufacturers to meet evolving customer demands while maintaining cost effectiveness and production efficiency.

Major Types of Metal Spinning Products

The metal spinning products market can be categorized based on product type and application requirements. Commonly produced components include cylindrical and conical shapes used in automotive exhaust systems aerospace housings and pressure vessels lighting fixtures and reflectors for commercial and residential use cookware and kitchen equipment industrial containers and tanks architectural and decorative metal components

Each product category serves a specific set of end users and contributes to overall market revenue. The ability to customize dimensions and shapes further enhances the adoption of metal spinning products across industries.

Material Analysis and Market Preferences

Material selection plays a crucial role in determining the performance and application of metal spinning products. Aluminum is widely preferred due to its lightweight nature corrosion resistance and ease of forming. Stainless steel is extensively used in applications requiring high strength temperature resistance and durability. Copper and brass are commonly used for electrical and decorative applications due to their conductivity and aesthetic appeal.

The growing emphasis on lightweight materials in automotive and aerospace manufacturing continues to drive demand for aluminum based metal spinning products. At the same time stainless steel remains essential for construction and industrial applications where structural integrity is critical.

Manufacturing Technology and Process Advancements

Technological innovation is a key driver shaping the metal spinning products market. The adoption of CNC metal spinning machines has significantly improved precision repeatability and production speed. These advanced systems enable manufacturers to produce complex geometries with minimal manual intervention resulting in higher productivity and reduced labor costs.

Automation and digital integration also support quality control and process optimization. Real time monitoring and data driven manufacturing practices enhance consistency and reduce defect rates. These advancements not only improve operational efficiency but also expand the application scope of metal spinning products.

End Use Industry Analysis

The automotive industry is one of the largest consumers of metal spinning products due to the need for lightweight and durable components such as exhaust systems wheel rims and structural parts. Aerospace manufacturers rely on metal spinning for producing high precision components that meet strict safety and performance standards.

The construction sector uses metal spinning products for architectural elements ventilation systems and structural components. The electronics industry benefits from metal spinning in the production of enclosures heat sinks and shielding components. Industrial machinery manufacturers utilize metal spinning products for tanks housings and pressure vessels.

The diversity of end use industries ensures stable demand and long term growth potential for the metal spinning products market.

Regional Market Insights

North America represents a significant share of the global metal spinning products market due to advanced manufacturing infrastructure and strong demand from aerospace and automotive industries. Europe follows closely with a focus on sustainable manufacturing and high quality engineering standards.

Asia Pacific is expected to witness the fastest growth during the forecast period driven by rapid industrialization urbanization and expansion of automotive and construction sectors. Countries such as China India and Japan are investing heavily in manufacturing capabilities which supports market expansion. Latin America and the Middle East and Africa also present emerging opportunities supported by infrastructure development and industrial growth.

Competitive Landscape and Market Structure

The metal spinning products market is moderately fragmented with the presence of both large multinational manufacturers and small to medium sized enterprises. CITIC Dicastal Wheel Manufacturing

- Standex ETG

- Samuel Metal Spinners

- Wenzel Metal Spinning

- Helmut Rübsamen (INDUS Holding)

- Enkei Wheels

- Yueling Wheels

- Zhejiang Wanfeng Auto Wheel

Continuous innovation and quality improvement remain critical success factors in this competitive environment.

Market Drivers Supporting Growth

Several factors contribute to the steady growth of the metal spinning products market. Increasing demand for precision engineered components across industries rising adoption of lightweight materials to improve energy efficiency advancements in CNC and automated manufacturing technologies cost effectiveness and material efficiency compared to alternative forming processes expanding infrastructure and industrial development in emerging economies

These drivers collectively support sustained market expansion and encourage investment in metal spinning capabilities.

Challenges and Market Constraints

Despite positive growth prospects the market faces certain challenges. High initial investment costs for advanced CNC machinery can be a barrier for small manufacturers. Skilled labor shortages and the need for technical expertise may also limit adoption in some regions. Additionally competition from alternative manufacturing processes such as stamping and casting can impact market growth in price sensitive applications.

However ongoing technological improvements and increasing awareness of the benefits of metal spinning are expected to mitigate these challenges over time.

Opportunities and Future Trends

The future of the metal spinning products market is shaped by emerging trends and opportunities. Increasing focus on sustainable manufacturing and waste reduction supports the adoption of metal spinning. Customization and low volume high precision production create new opportunities in specialized industries. Integration of digital manufacturing and smart factory concepts enhances efficiency and quality control.

The growing use of metal spinning in renewable energy equipment medical devices and advanced transportation systems further expands the market’s potential.

Market Forecast and Long Term Outlook

The metal spinning products market is expected to maintain steady growth through 2033 supported by consistent demand from core industries and technological advancements. Increasing investments in industrial manufacturing and infrastructure development create a favorable environment for market expansion.

As manufacturers continue to innovate and optimize production processes metal spinning is likely to gain wider acceptance as a preferred metal forming technique. The market’s ability to balance performance cost efficiency and sustainability positions it well for long term success.

Conclusion

The global metal spinning products market represents a dynamic and evolving segment of the manufacturing industry. Driven by demand for precision engineered lightweight and durable components the market continues to expand across diverse end use sectors. Technological advancements in CNC metal spinning and increasing industrial investments strengthen growth prospects.

With favorable market drivers expanding applications and emerging opportunities the metal spinning products market is poised for steady growth during the forecast period. Companies that focus on innovation quality and customization are well positioned to capitalize on this expanding market and achieve long term competitive advantage.