The global nanoclays market is witnessing strong momentum as industries increasingly adopt advanced materials to improve performance, sustainability, and cost efficiency. Nanoclays are nanoscale layered mineral silicates that enhance mechanical strength, thermal stability, and barrier properties when incorporated into polymers and composites. These materials are widely used across packaging, automotive, aerospace, construction, electronics, and healthcare industries due to their ability to deliver high performance improvements at low loading levels.

Nanoclays have emerged as a critical component in the development of next generation materials that meet evolving regulatory, environmental, and performance standards. Their ability to improve durability while reducing material usage aligns with global trends toward lightweight design and sustainable manufacturing. As industries continue to innovate and modernize, the demand for nanoclays is expected to increase steadily across both developed and emerging economies.

According to persistence market research The global nanoclays market size is likely to be valued at US$ 2.6 Billion in 2026 and is expected to reach US$ 4.2 Billion by 2033, growing at a CAGR of 7.1 percent during the forecast period from 2026 to 2033.

The Nanoclays market is driven by accelerating demand for lightweight materials in the Automotive and Aerospace sectors, where weight reduction directly improves fuel efficiency and extends electric vehicle range. Additionally, rising sustainability concerns in Packaging industries are propelling adoption of nanoclay reinforced films, which can reduce oxygen permeability by up to seventy percent and prevent fifteen to twenty percent of perishable food losses in North America alone, thereby addressing global food waste challenges. Regulatory frameworks promoting circular economy initiatives and stricter environmental compliance are further strengthening the adoption of nanoclay based solutions across multiple industries.

Fundamental Properties of Nanoclays

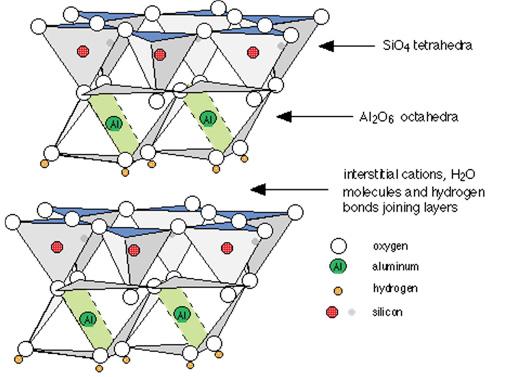

Nanoclays possess unique structural and chemical properties that differentiate them from conventional fillers. Their layered silicate structure allows for uniform dispersion within polymer matrices, resulting in significant enhancements in material performance. Even at low concentrations, nanoclays improve tensile strength, stiffness, and heat resistance.

Another important property of nanoclays is their exceptional barrier performance. When properly dispersed, nanoclays create a tortuous path that restricts the movement of gases and moisture. This feature is especially valuable in food and pharmaceutical packaging applications where product freshness and shelf life are critical. Nanoclays also contribute to flame retardancy and chemical resistance, further expanding their applicability.

Market Segmentation by Product Type

The nanoclays market can be segmented based on product type, each offering distinct advantages for specific applications. Natural nanoclays such as montmorillonite dominate the market due to their availability, cost effectiveness, and strong performance characteristics. These nanoclays are widely used in packaging, automotive, and construction applications.

Synthetic nanoclays are gaining attention for specialized applications requiring precise control over particle size and purity. These materials are commonly used in high end electronics, medical devices, and advanced research applications. The growing demand for tailored material solutions is expected to drive steady growth in the synthetic nanoclays segment.

Market Segmentation by Application

Based on application, packaging represents the largest segment of the global nanoclays market. The need for enhanced barrier properties, reduced material usage, and improved sustainability is driving adoption across food, beverage, and pharmaceutical packaging.

Automotive and aerospace applications form another significant segment, supported by increasing demand for lightweight and high strength materials. Construction applications follow closely, driven by infrastructure development and demand for durable building materials. Other application segments include electronics, healthcare, paints, coatings, and adhesives, each contributing to overall market growth.

Regional Market Analysis

· North America holds a significant share of the global nanoclays market, supported by strong demand from packaging, automotive, and construction industries. The region benefits from advanced manufacturing capabilities, high research activity, and strong regulatory support for sustainable materials.

· Europe represents another major market, driven by stringent environmental regulations and strong emphasis on lightweight and recyclable materials. Automotive innovation and packaging sustainability initiatives play a key role in driving demand across the region.

· Asia Pacific is expected to witness the fastest growth during the forecast period. Rapid industrialization, expanding automotive production, and growing packaging demand in countries such as China, India, and Japan are key growth drivers. Increasing investments in infrastructure and manufacturing further strengthen regional market prospects.

· Latin America and the Middle East and Africa are emerging markets for nanoclays. Growing construction activity, improving industrial capabilities, and rising awareness of advanced materials are expected to support gradual market expansion in these regions.

Key Market Growth Drivers

Several factors are driving growth in the global nanoclays market. Increasing demand for lightweight materials across transportation sectors remains a primary driver. Weight reduction directly contributes to fuel efficiency, lower emissions, and improved performance, making nanoclays an attractive solution.

Sustainability concerns are another major growth factor. Nanoclays enable material reduction and improved recyclability, supporting circular economy initiatives. Their role in reducing food waste through improved packaging performance further enhances their value proposition.

Technological advancements in nanocomposite processing and dispersion techniques are also accelerating market growth. Improved manufacturing methods enhance consistency and performance, making nanoclays more accessible to a wider range of industries.

Market Challenges and Restraints

Despite strong growth potential, the nanoclays market faces certain challenges. Achieving uniform dispersion within polymer matrices can be technically complex, requiring specialized processing techniques. Inconsistent dispersion can limit performance benefits and hinder adoption.

Cost considerations also play a role, particularly for small and medium manufacturers. While nanoclays reduce material usage, initial formulation and processing costs can be higher than conventional fillers. Addressing these challenges through innovation and scale will be critical for sustained market growth.

Competitive Landscape and Key Players

The global nanoclays market is moderately competitive, with a mix of multinational corporations and specialized material suppliers. Leading companies focus on expanding product portfolios, improving dispersion technologies, and strengthening partnerships with end use industries.

Key players operating in the global nanoclays market include BYK Chemie, Nanocor, Southern Clay Products, Elementis, Imerys, BASF, Clariant, Evonik Industries, Cabot Corporation, and Minerals Technologies. These companies invest heavily in research and development to enhance product performance and address evolving customer needs.

Future Outlook and Growth Forecast

The future outlook for the global nanoclays market remains highly positive. Strong demand from packaging, automotive, aerospace, and construction industries will continue to drive market expansion. Sustainability initiatives and regulatory support for environmentally friendly materials will further strengthen adoption.

Emerging economies are expected to play a critical role in future growth as industrialization and infrastructure development accelerate. Companies that focus on innovation, quality, and sustainability will be well positioned to capitalize on long term market opportunities.

Key Market Growth Drivers

Several factors are driving growth in the global nanoclays market. One of the most important drivers is the increasing demand for lightweight and high performance materials in automotive and aerospace industries. Weight reduction directly improves energy efficiency and reduces operating costs making nanoclays an attractive solution.

Sustainability concerns are another major growth driver. Packaging manufacturers are adopting nanoclays to reduce material usage extend shelf life and minimize food waste. These benefits align with global sustainability initiatives and consumer demand for eco friendly packaging solutions.

Technological advancements in polymer nanocomposites are also supporting market growth. Improved dispersion techniques and processing methods have enhanced the performance and consistency of nanoclay based materials. Additionally increasing investment in research and development is expanding application possibilities and accelerating commercialization.

Regulatory Environment and Sustainability Influence

Regulatory frameworks play a crucial role in shaping the nanoclays market. Governments across major regions are implementing policies that encourage lightweight materials recyclability and reduced environmental impact. These regulations are driving adoption of nanoclay reinforced materials across automotive packaging and construction sectors.

Sustainability initiatives such as circular economy programs are further supporting market growth. Nanoclays enable material reduction and performance enhancement which contribute to resource efficiency. Manufacturers that integrate nanoclays into their products are better positioned to meet regulatory requirements and sustainability targets.

Competitive Landscape and Industry Structure

The global nanoclays market features a mix of established material suppliers and specialized nanotechnology companies. Leading players focus on developing high quality nanoclays with consistent particle size and performance characteristics. Product innovation and technical support are key competitive factors.

Smaller companies often target niche applications or provide customized solutions for specific industries. Strategic partnerships between nanoclay producers polymer manufacturers and research institutions are common and help accelerate product development. Competition in the market is influenced by pricing quality scalability and application expertise.

Role of Research and Development

Research and development activities are central to the evolution of the nanoclays market. Scientists and engineers are exploring new modification techniques to improve compatibility with different polymers. These efforts enhance dispersion and unlock additional performance benefits.

Collaborative research initiatives between academia and industry are expanding knowledge and driving innovation. Advances in nanocomposite processing are enabling broader adoption and cost efficiency. As research continues to progress nanoclays are expected to find new applications in emerging technologies and advanced manufacturing.

Future Outlook and Growth Forecast

The future outlook for the global nanoclays market remains highly positive. Strong demand from automotive aerospace packaging and construction industries is expected to sustain growth through 2033. Emerging economies will play an increasingly important role as industrial activity and infrastructure development expand.

Ongoing innovation regulatory support and sustainability initiatives will further strengthen market prospects. Nanoclays will continue to enable material efficiency performance enhancement and environmental responsibility across industries.

Overall the global nanoclays market is poised for steady and meaningful expansion. Its ability to address critical challenges such as weight reduction resource efficiency and sustainability ensures long term relevance and attractive opportunities for manufacturers investors and technology developers worldwide.